Lucullus Software

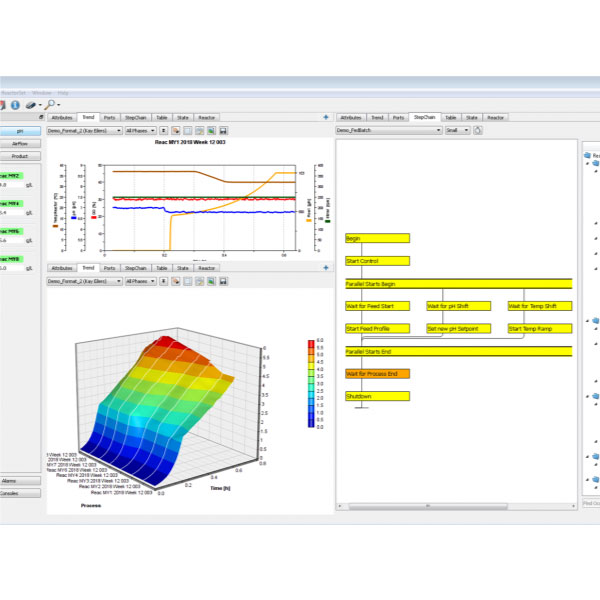

Lucullus Process Information Management System offers a new dimension in upstream bioprocess data management. Where classic SCADA solutions are limited to data acquisition and supervisory control functions, Lucullus integrates functionalities activities around creating and planning of recipes, reactor allocation, Design of Experiments, media preparation, media component trace-ability, data analysis, data mining, automatic reporting and modelling. The integration of all these functions into one comprehensive software solution saves the scientists time since all data is stored in one central Oracle© database. No more need for data export and import between different solutions, Lucullus integrates all functions needed for complete data management of your upstream process.

The ever increasing amount of process data generated by more sensors in smaller parallel bioreactor systems needs advanced software to turn this data into useful information. Lucullus PIMS offers a new dimension in data processing. Data management and data analysis is key for the future of R&D and process development in pharmaceutical industry. Lucullus PIMS software allows the user to monitor and control bioprocesses and offers an extensive toolbox for analyzing process data c ross platforms. Process information can be generated based on data generated in different brands of bioreactor types and wide range of different cultivation volumes. The combination of the software with the broad range of Applikon Bioreactor Systems offer the user a unique system for validatable fast track development and basic research.

Features

- Functionality for Design of Experiments, Reactor Planning, Media Preparation and Tracking, Parallel Processing, SCADA, Data Mining and Batch Reporting.

- Validatable fast track development and basic research.

- Advanced software to turn this data into useful information.

- Data management & data analysis.

Applications

- Research and process development applications.

- Small scale production.

- Longterm mamallian cell cultivations.

- Short term microbial cultures.

Idea & Recipe

Make your process idea come true with an intuitive tool to create your process control strategy (recipe)

- Define a Step Chain, which is a programming language, based on the user process that allows the user to define different flows of execution with looping, branching and computation of variables.

- Specifying the reactor and devices to be used in the recipe.

- Integrate alarms in the recipe ( Notification, Email, and SMS alarms).

Planning

Define everything in advance with an intuitive workflow to start the processes later with minimal effort

- Plan recipes using an intuitive workflow.

- Define process parameters by integrating the design of your experiment (as well as DOE).

- Schedule and allocate bioreactors in the labs (Calendar).

- Manage samples efficiently (apply sampling strategies, define methods and prepare tubes, for instance by printing labels).

- Sample interactively during execution (reminder, information, exact timing of stamps/volumes).

- Retrieve data automatically from at-line analyzers using barcodes (E.g. Vicell, Nova pHOx, Nova Flex and etc.) .

- Assign media/feeds to be used and initiate preparation process.

Preparation

Media preparation, storage and component trace-ability and media optimization

- Exercise advanced management of compound and ingredient storage.

- Create Lots from recipes (generate and print barcode label).

- Monitor usage of compounds from storage.

- Automate the media kitchen (pH meter, scales, etc.).

- Select Lots at process start (use barcode scanner).

- Optimize media.